المنتجات الساخنة

quadropol® vertical roller mill thyssenkrupp Polysius

网页For the 4,000 tons per day kiln line Shiva Cement Ltd. contracted a quadropol® vertical roller mill for grinding pet coke with a QMK² 32/16. The same mill size QMK² 32/16 is running

Contact

Modeling of energy consumption factors for an industrial

网页2022年5月9日 By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted a novel strategy to explore relationships between VRM monitored operational

Contact

A cement Vertical Roller Mill modeling based on the

网页2022年10月1日 Vertical roller mills (VRM) are widely used to grind, dry, and select powders from various materials in the cement, electric power, metallurgical, chemical, and

Contact

Operational parameters affecting the vertical roller mill

网页2017年4月1日 Among these devices, vertical roller mills have an important position in cement and mining industry. In literature, there are many studies performed in cement

Contact

Review on vertical roller mill in cement industryits

网页2021年1月1日 A two-compartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now

Contact

(PDF) Performance Evaluation of Vertical Roller Mill in

网页2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from Find,

Contact

Operational parameters affecting the vertical roller mill

网页2017年4月1日 The results of setting time, compressive strength, soundness and moisture content showed that both gypsum and hemihydrate had the same performance in vertical

Contact

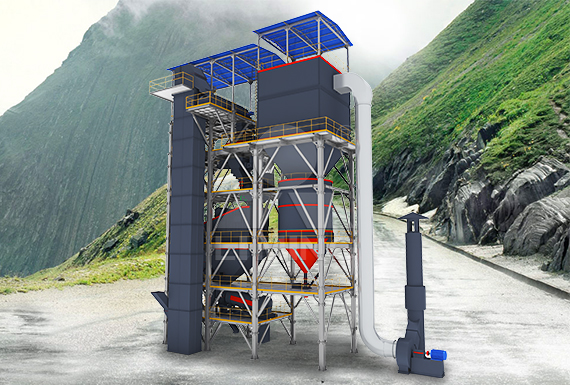

Vertical Roller Mill Operation in Cement Plant

网页The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process. In recent years, the VRM cement

Contact

VRM optimisation International Cement Review

网页2015年7月29日 Most new cement plants utilise vertical roller mills (VRM) for raw material grinding and preparation. Taking a step-by-step look at the entire roller milling process, Kline Consulting recommends

Contact

Operational parameters affecting the vertical roller mill

网页2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding.

Contact

Cement Industry Loesche

网页2023年6月2日 LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the

Contact

(PDF) Performance Evaluation of Vertical Roller Mill in

网页2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the

Contact

PROCESS CONTROL FOR CEMENT GRINDING IN

网页2017年10月27日 The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 30-40% associated with other grinding mills. The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics also dynamics changes within 2-4 minutes.

Contact

Energy-Efficient Technologies in Cement

网页2016年10月5日 In this chapter an introduction of widely applied energy-efficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over

Contact

Our modern vertical roller mill takes you further

网页Our vertical roller mill for raw, cement, and slag grinding applications offers the best energy efficiency, easy operation, and lowest cost of ownership. The OK™ Mill is offered in a complete size range, including 3-, 4- and 6

Contact

Vertical roller mill for raw Application p rocess materials

网页2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills. These days, the vertical roller mills have been widely adopted. A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table.

Contact

VRM optimisation International Cement Review

网页2015年7月29日 Most new cement plants utilise vertical roller mills (VRM) for raw material grinding and preparation. Taking a step-by-step look at the entire roller milling process, Kline Consulting recommends routine

Contact

Copper ore grinding in a mobile vertical roller mill pilot plant

网页2015年3月10日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium. Operational experience from the United States' first vertical mill for cement grinding. Cement Industry Technical Conference, IEEE (2005),

Contact

Vertical Roller Mill for Cement Raw Material

网页The vertical mill’s drying capacity is strong, and the waste heat of the kiln can be used to dry the raw materials with a moisture content of 8% or higher. The air ring area, the air ring angle, and the dam ring’s height can

Contact

Modeling of energy consumption factors for an

网页2022年9月12日 By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted (crushers and mills) to reduce the size of raw materials and clinker 1–3. In the mid-1990s, the

Contact

Cement Industry Loesche

网页2023年6月2日 LOESCHE Vertical Roller Mill: We do much more than rely solely on our unbeatable technology. Our designers are constantly coming up with new ideas and even more dependable components to reduce the

Contact

Our modern vertical roller mill takes you further

网页Our vertical roller mill for raw, cement, and slag grinding applications offers the best energy efficiency, easy operation, and lowest cost of ownership. The OK™ Mill is offered in a complete size range, including 3-, 4- and 6

Contact

VRM optimisation International Cement Review

网页2015年7月29日 Most new cement plants utilise vertical roller mills (VRM) for raw material grinding and preparation. Taking a step-by-step look at the entire roller milling process, Kline Consulting recommends routine

Contact

Copper ore grinding in a mobile vertical roller mill pilot plant

网页2015年3月10日 Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchers. It has been used mainly for cement raw meal grinding applications where crushing, grinding, classifying and drying operations were combined in a single unit.

Contact

Vertical roller mill for raw Application p rocess materials

网页2016年1月4日 The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills. These days, the vertical roller mills have been widely adopted. A)Structure (1) The rollers are hydraulically pressed against a disc table and the feed is ground between the rollers and the disc table.

Contact

Plant engineering solutions for any mission

网页2023年6月2日 Since 1906 worldwide market leader in designing, manufacturing and servicing vertical roller mills for the cement, power and industrial minerals industries. Plant engineering solutions for any mission

Contact

Holderbank Cement engineering book Archive

网页2021年1月28日 This stone deals in first place with roller mills for raw material processing. For grinding coal, slag, cement, etc., adaptations to mills and systems have to be made. 2. FUNCTIONS OF THE ROLLER MILL The vertical roller mill fulfills 4 main functions in one compact piece of equipment: ¢ Grinding ? Drying ¢ Separation ¢ Transport

Contact

How many types of cement mills are there?

网页Cement milling is the process of grinding the clinkerinto fine powder. It is an essential process in the manufacturing of cement. There are various types of cement mills that are used in the milling process. Each type of cement mill has its unique characteristics and is suitable for different purposes.

Contact

Vertical Roller Mill for Cement Raw Material

网页The vertical mill’s drying capacity is strong, and the waste heat of the kiln can be used to dry the raw materials with a moisture content of 8% or higher. The air ring area, the air ring angle, and the dam ring’s height can

Contact