المنتجات الساخنة

Effects of dry grinding on the structure and granularity of

网页2014年3月1日 The aim of this work is to study the change of the structure and phase of calcite during the dry grinding process. The results might be of useful scientific value for practical utilization of ultrafine calcium carbonate in fields such as materials, powder

Contact

Fine dry comminution of calcium carbonate in a Hicom

网页2002年3月1日 These tests have demonstrated that the Hicom pilot plant can be used to efficiently grind calcium carbonate to fine sizes. This ability to grind this calcium

Contact

Effects of Grinding Aids Used in Grinding Calcium

网页2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of

Contact

(PDF) Effects of Grinding Aids Used in Grinding Calcium

网页2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of

Contact

A critical review on the mechanisms of chemical additives

网页2020年7月1日 1. Introduction The term chemical additives or grinding aids (GAs) refers to any substance which results in increased grinding efficiency and reduction in power

Contact

Calcium Carbonate Grinding Union Process

网页Factors for Calcium Carbonate Grinding. The grind of the calcium carbonate depends upon the application for which it is being used. With our Attritor grinders available for both dry

Contact

Calcium Carbonate NETZSCH GrindingDispersing

网页2023年6月7日 Calcium carbonate (CaCO 3), which occurs primarily in the form of the minerals calcite and aragonite, is one of the most prevalent compounds on Earth.

Contact

Wet grinding of CaCO3 ScienceDirect

网页2015年3月1日 In this study, the dependency of the pressure filtration properties of wet ground calcium carbonate (GCC) slurries on the grinding result obtained by a stirred

Contact

Dry Grinding of Calcium Carbonate Professional

网页2019年6月14日 Dry grinding of calcium carbonate means to obtain ground calcium carbonate powder by grinding slumps of limestone or marble, rather than the slurry

Contact

How to Choose a Calcium Carbonate Grinding Mill

网页2022年8月13日 Production method of calcium carbonate powder Before choosing a grinding mill, you need to understand how calcium carbonate is produced. At present,

Contact

Fine dry comminution of calcium carbonate in a Hicom

网页2002年3月1日 The Hicom mill is a high-intensity tumbling mill that can be used for fine and ultra-fine media grinding. Recent investigations on fine dry grinding with the Hicom 25 pilot plant, operating in closed circuit with an IAC 200 Inprosys high-efficiency classifier, have indicated that this milling combination is well suited to the efficient production of fine

Contact

Case study for production of calcium carbonate from

网页2016年6月1日 1. Introduction Steelmaking slags are rock-like by-products of the steelmaking industry, consisting principally of calcium, magnesium, and aluminium silicates, as well as iron and manganese. Depending on the steel production process, different slag types are produced.

Contact

Effects of Grinding Aids Used in Grinding Calcium

网页2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO 3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or organic resin affects the dispersion of the minerals and ultimately down-stream product properties in consumer industries

Contact

Calcium Carbonate Fillers SpringerLink

网页2017年3月1日 Calcium carbonate is one of the principal mineral fillers used in polymer applications, with the world consumption being over ten million tonnes annually. It is an abundant natural material; with ideal properties for use as a filler in all types of polymer. It occurs in large, relatively pure, deposits, close to the surface and easily mined.

Contact

(PDF) Calcium Carbonate Synthesis, Optimization and

网页2020年7月30日 The grinding, drying and separating process was carried out for 25, 30 and 10 min respectively.

Contact

Preparation and analysis of a polyacrylate grinding aid for

网页2014年3月1日 The grinding aid was used in the ultrafine wet grinding of grinding calcium carbonate (GCC) exhibited a remarkably enhancement in the fluidity of the GCC slurry and the content of GCC particles that with sizes smaller than 2 μm increased by 9.3%.

Contact

Calcium carbonate nano- and microparticles: synthesis

网页2021年10月7日 Calcium carbonate micro- and nanoparticles are considered as chemically inert materials. Therefore, they are widely considered in the field of biosensing, drug delivery, and as filler material in plastic, , paint, sealant, and adhesive industries. The unusual properties of calcium carbonate-based nanomaterials, such as biocompatibility,

Contact

On Fragmentation and Agglomeration Phenomena in an

网页The aim of this work to produceis ground calcium carbonate by dry grinding using a micronizer called “Planetary Mill” under various operating conditions with and without addition of oleic acid

Contact

Wet grinding of CaCO3 ScienceDirect

网页2015年3月1日 Ground calcium carbonate Operational conditions Pressure filtration Cake resistance Porosity 1. Introduction The separation of mineral particles from a liquid in the industry is always affected by the upstream process conditions applied during size reduction by the grinding circuit.

Contact

Dry Grinding of Calcium Carbonate Professional

网页2019年6月14日 June 14, 2019 by mineralprocess Dry grinding of calcium carbonate means to obtain ground calcium carbonate powder by grinding slumps of limestone or marble, rather than the slurry version.

Contact

Fine dry comminution of calcium carbonate in a Hicom

网页2002年3月1日 Grinding 1. Introduction Located at Hicom's test facility in Sydney Australia, the Hicom dry pilot plant consists of a Hicom 25 nutating mill operating in closed circuit with an Inprosys IAC 200 high-efficiency classifier.

Contact

Calcium Carbonate Fillers SpringerLink

网页2017年3月1日 Ground (natural) calcium carbonates (GCC) is a critical and functional mineral for , and there is no doubt that it will continue to be one of the principal fillers used by the polymer industry. While GCC fillers are

Contact

Optimization of Milling Procedures for Synthesizing Nano

网页2020年3月14日 The possibility of obtaining calcium carbonate nanoparticles from <i>Achatina fulica</i> shell through mechanochemical synthesis to be used as a modifying filler for polymer materials has been studied. The process of obtaining calcium carbonate nanopowders includes two stages: dry and wet milling processes. At the first stage, the

Contact

Calcium carbonate nano- and microparticles: synthesis

网页2021年10月7日 Calcium carbonate micro- and nanoparticles are considered as chemically inert materials. Therefore, they are widely considered in the field of biosensing, drug delivery, and as filler material in plastic, , paint, sealant, and adhesive industries. The unusual properties of calcium carbonate-based nanomaterials, such as biocompatibility,

Contact

Precipitated Calcium carbonate production,

网页2017年1月1日 Calcium carbonate (CaCO3) is the most widely used filler material in , paint, plastic, , ceramic, cosmetic, medicine and other industries. and prepared by either wet or dry grinding

Contact

On Fragmentation and Agglomeration Phenomena in an

网页The aim of this work to produceis ground calcium carbonate by dry grinding using a micronizer called “Planetary Mill” under various operating conditions with and without addition of oleic acid

Contact

[PDF] Effects of Grinding Aids Used in Grinding Calcium

网页2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or organic resin affects the dispersion of the minerals and ultimately down-stream product properties in consumer industries

Contact

Wet grinding of CaCO3 ScienceDirect

网页2015年3月1日 Ground calcium carbonate Operational conditions Pressure filtration Cake resistance Porosity 1. Introduction The separation of mineral particles from a liquid in the industry is always affected by the upstream process conditions applied during size reduction by the grinding circuit.

Contact

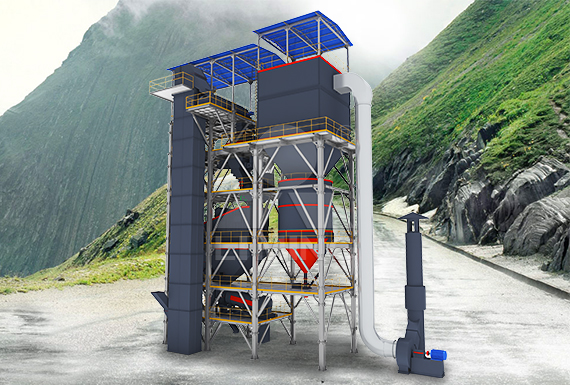

Customize Suitable Calcium Carbonate Plant DASWELL

网页2022年9月1日 A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications. Both dry grinding and wet grinding are available. Grinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end product.

Contact

Calcium carbonate ultrafine powder grinding and

网页2023年5月30日 The processing of ground calcium carbonate is simply the process of using crushing and grinding equipment to process calcium carbonate minerals into various powders that can meet the requirements of industrial applications. The common processing equipment of ground calcium carbonate produced by large-scale dry process

Contact