المنتجات الساخنة

Dynamic simulation of grinding circuits ScienceDirect

网页2004年11月1日 To develop a grinding circuit, it is a simple task of drag and drop of appropriate blocks (grinding units) from the library into a new workplace, and then the blocks can be linked into a grinding circuit by click and drag of the mouse.

Contact

Development of a grinding model based on flotation

网页2021年6月1日 1. Introduction Flotation is the most widely used technology in mineral processing, and thousands of tons of ore are produced worldwide every day.

Contact

Reducing the energy footprint of grinding circuits: the

网页2017年7月1日 The Coalition for Energy Efficient Comminution (CEEC) estimated that e fragmentatio accounts for 53% of the nergy consumed on a typical mine site (CEEC,

Contact

Grinding Circuit an overview ScienceDirect Topics

网页Grinding Circuit. Grinding circuits are fed at a controlled rate from the stockpile or bins holding the crusher plant product. From: Wills' Mineral Processing Technology (Eighth

Contact

A process mineralogy approach to study the efficiency of

网页2020年12月3日 As can be seen in Fig. 6B, the minerals present in the product of open-circuit mill, in the order of abundance, include molybdenite, which is mostly free and has

Contact

Characterisation of Metal Debris in Grinding and Flotation

网页2021年9月1日 A remarkable range of metal debris morphologies and sizes in the grinding and flotation circuits. • Upstream equipment fragments such as loader teeth and high

Contact

Dynamic simulation of industrial grinding circuits

网页2020年11月1日 Based on an existing mineral processing plant simulation library, this research addresses these problems by (1) developing a mineral liberation model aiming

Contact

Reinforcement Learning for Grinding Circuit Control in

网页2019年11月15日 The goal of the grinding circuit is two-sided; to maximize the throughput of ore, and minimize the resulting particle size of the ground ore within some acceptable

Contact

(PDF) Optimization and performance of grinding circuits:

网页2020年1月16日 Currently, the grinding circuits are inefficient in achieving the aspired product fineness of xP,80 = 125 μm even at low to normal throughputs (450-600 t/h). An

Contact

Intelligent Optimal-Setting Control for Grinding Circuits of

网页2009年11月1日 During the operation of a grinding circuit (GC) in mineral processing plant the main purpose of control and optimal operation is to control the product quality index,

Contact

Dynamic simulation of grinding circuits ScienceDirect

网页2004年11月1日 A flexible and powerful dynamic simulation approach to grinding circuit simulation has recently been developed in CSIRO Minerals. The MATLAB/SIMULINK graphical programming environment has been used to construct a library of dynamic mathematical models of a number of key grinding and separation devices and to link

Contact

Benefits of process control systems in mineral processing

网页2015年8月1日 An economic real-time optimisation (RTO) layer coordinates the setpoints of a linear model predictive controller (MPC) of the grinding circuit. Assumed measurable, mineral liberation data feeds the RTO to update the particle size target parameter in an internal model predicting the flotation concentrate mass flow rate, grade, and recovery.

Contact

Autogenous and Semi-Autogenous Mills ScienceDirect

网页2016年1月1日 This chapter examines the developments in the design and operation of both autogenous and semi-autogenous systems of grinding ores for their size reduction and for the liberation of the economic minerals for extraction in downstream metallurgical operations. 9.2. Design of AG/SAG Mills

Contact

Lithium deportment by size of a calcined spodumene ore

网页2022年10月31日 The XRD analysis for the open circuit grinding (see Fig. 5 a) shows that a significant amount of β-spodumene was deported to the finest size fraction, leading to the lithium grade of 0.65% which

Contact

(PDF) Power-based comminution calculations

网页2013年10月16日 Ausgrind is Ausenco's in-house program used for power-based comminution calculations. Proprietary calculations have been developed and reconciled with unit process operation and benchmarked

Contact

Energy Use of Fine Grinding in Mineral Processing

网页2013年12月18日 F ine grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered untreatable, it can entail high costs in terms of energy consumption and media use.

Contact

(PDF) Optimization and performance of grinding circuits:

网页2020年1月16日 Currently, the grinding circuits are inefficient in achieving the aspired product fineness of xP,80 = 125 μm even at low to normal throughputs (450-600 t/h). An evaluation and optimization...

Contact

Modeling of grinding and classification circuits as applied

网页2009年1月13日 In the mineral industry, stages of grinding, classification, and recovery circuits contribute to the improvement of yields in terms of production of a product and improving the grade value in concentrate recovery.

Contact

Minerals Free Full-Text Dynamic Monitoring of Grinding

网页2020年9月19日 Abstract Reliable control of grinding circuits is critical to more efficient operation of concentrator plants. In many cases, operators still play a key role in the supervisory control of grinding circuits but are not always able to act timely to deal with disturbances, such as changes in the mill feed.

Contact

Sungun Copper grinding circuit flow sheet.

网页In Hadizadeh et al. [92], an advanced distributed control system (DCS) is developed for the successful control of mineral processing plants, presenting the basis of an expert fuzzy supervisory...

Contact

Autogenous and Semi-Autogenous Mills ScienceDirect

网页2016年1月1日 This chapter examines the developments in the design and operation of both autogenous and semi-autogenous systems of grinding ores for their size reduction and for the liberation of the economic minerals for extraction in downstream metallurgical operations. 9.2. Design of AG/SAG Mills

Contact

Minerals Free Full-Text Optimizing

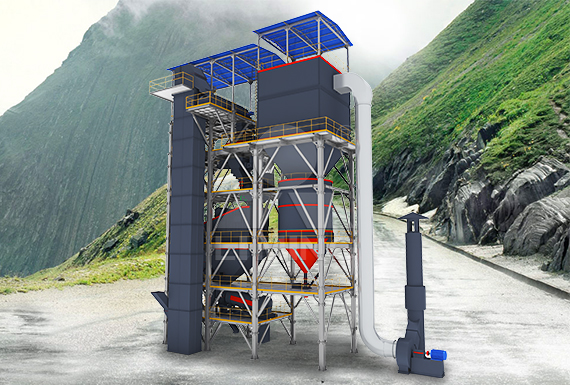

网页2016年12月2日 A standard crushing and grinding circuit is shown in Figure 1. It is commonly referred to as a SABC circuit, for Semi-Autogenous Ball mill Crusher (SABC).

Contact

Lithium deportment by size of a calcined spodumene ore

网页2022年10月31日 The XRD analysis for the open circuit grinding (see Fig. 5 a) shows that a significant amount of β-spodumene was deported to the finest size fraction, leading to the lithium grade of 0.65% which

Contact

(PDF) Power-based comminution calculations

网页2013年10月16日 Ausgrind is Ausenco's in-house program used for power-based comminution calculations. Proprietary calculations have been developed and reconciled with unit process operation and benchmarked

Contact

Energy Use of Fine Grinding in Mineral Processing

网页2013年12月18日 F ine grinding is becoming an increasingly common unit operation in mineral processing. While fine grinding can liberate ores that would otherwise be considered untreatable, it can entail high costs in terms of energy consumption and media use.

Contact

Our Dynamic HPGR Technology for Mineral Grinding Weir

网页Used in mining applications for the last 30 years, HPGR technology has streamlined the transition between mineral grinding and crushing by accepting larger-sized particles compared to ball mills, and producing finer-sized particles than cone crushers. Overview Services and Maintenance Overview

Contact

(PDF) Optimization and performance of grinding circuits:

网页2020年1月16日 Currently, the grinding circuits are inefficient in achieving the aspired product fineness of xP,80 = 125 μm even at low to normal throughputs (450-600 t/h). An evaluation and optimization...

Contact

IsaMill Technology Used in Effecient Grinding Circuits

网页18 小时之前 IsaMill™ OPERATION Grinding Mechanism The IsaMill™ is a horizontally stirred mill consisting of a series of 8 discs rotating around a shaft driven through a motor and gearbox. The discs operate at tip speeds of 21-23m/s resulting in high energy intensities of up to 300kW/m3. Figure 2 illustrates the layout of the IsaMill™.

Contact

Grinding in Ball Mills: Modeling and Process Control

网页2012年6月1日 Grinding Circuit Modeling and Simulation of Particle Size Control at Siilinjärvi Concentrator. International Journal of Mineral Processing, Vol. 96,2010, 70-78. 10.1016/j.minpro.2010.05.001 Google Scholar

Contact

Relationship between SAG mill power draw, bearing

网页Context 1 is believed that, these rules can cover all "expected" situations in the grinding circuit. The complete sets of rules are listed in Appendix 1. Figure 5 shows the relationship...

Contact